|

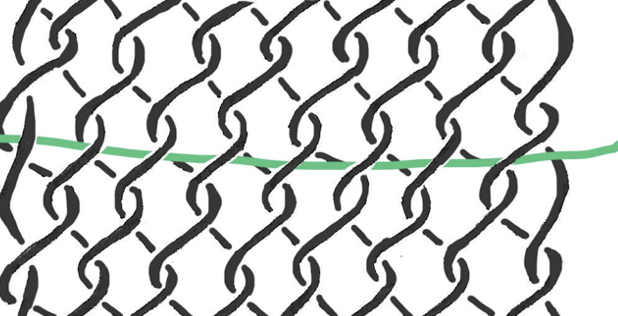

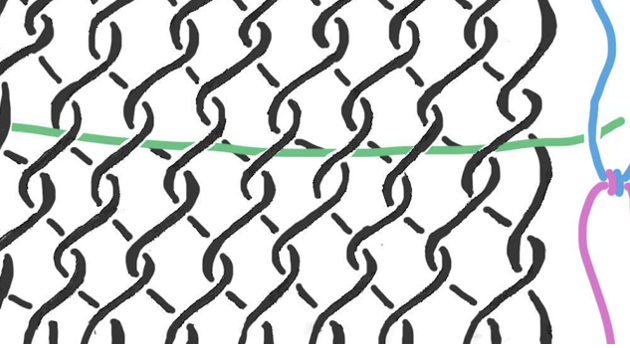

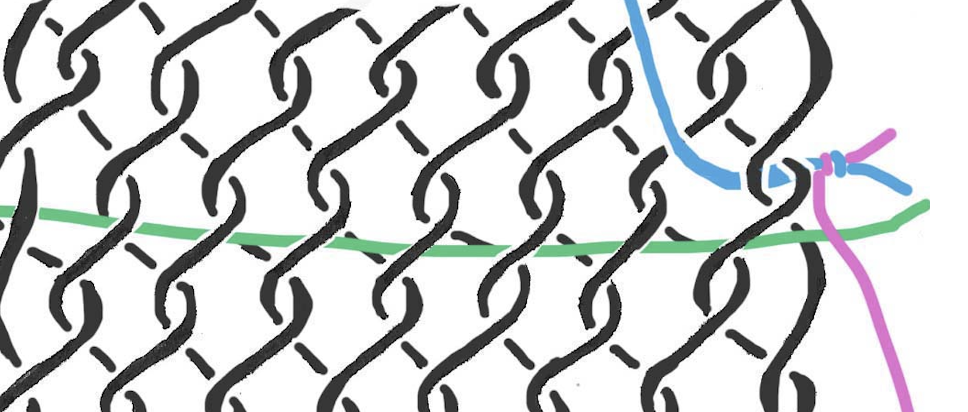

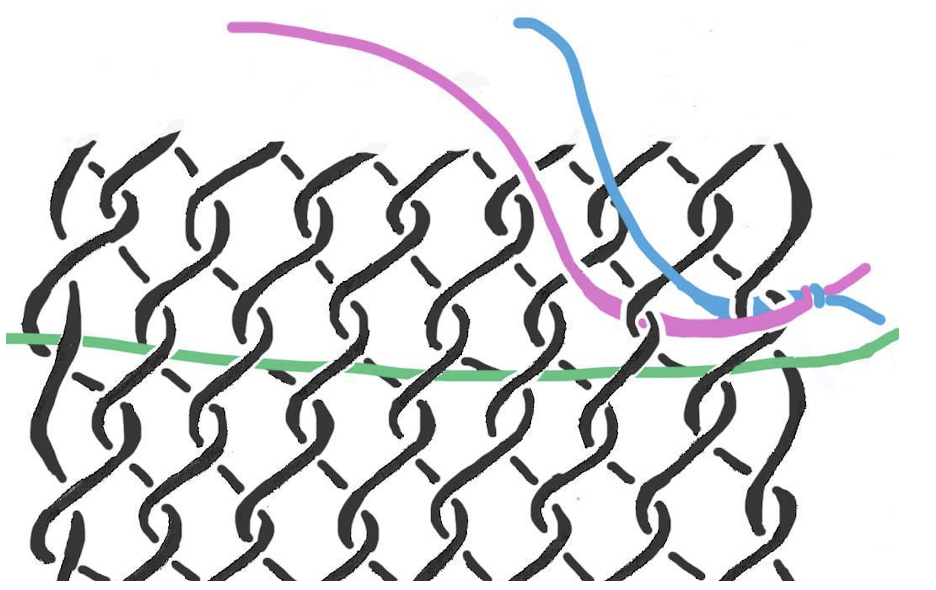

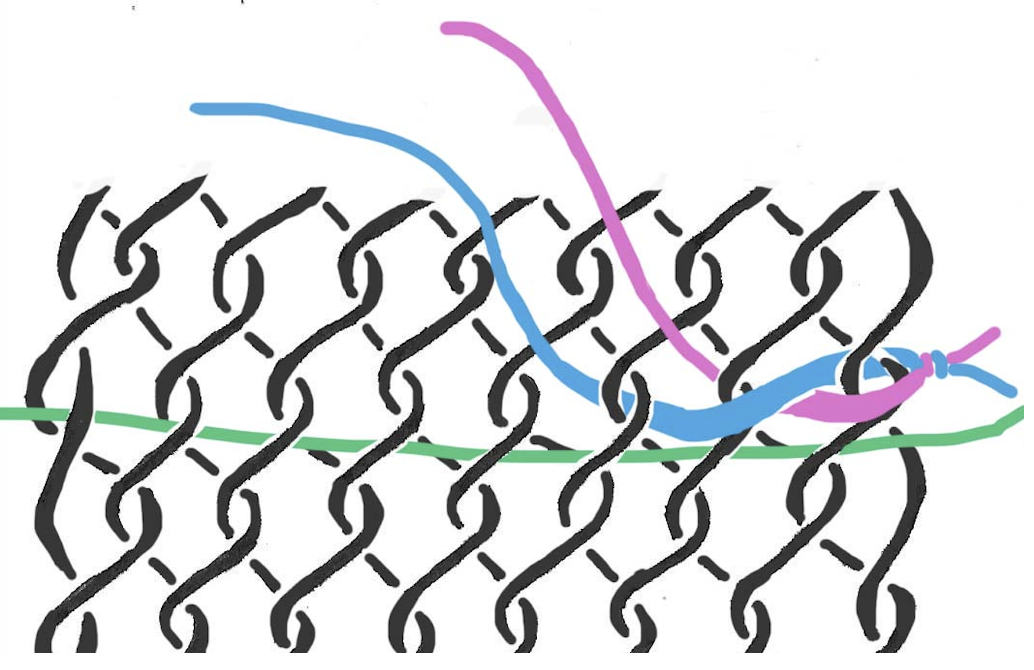

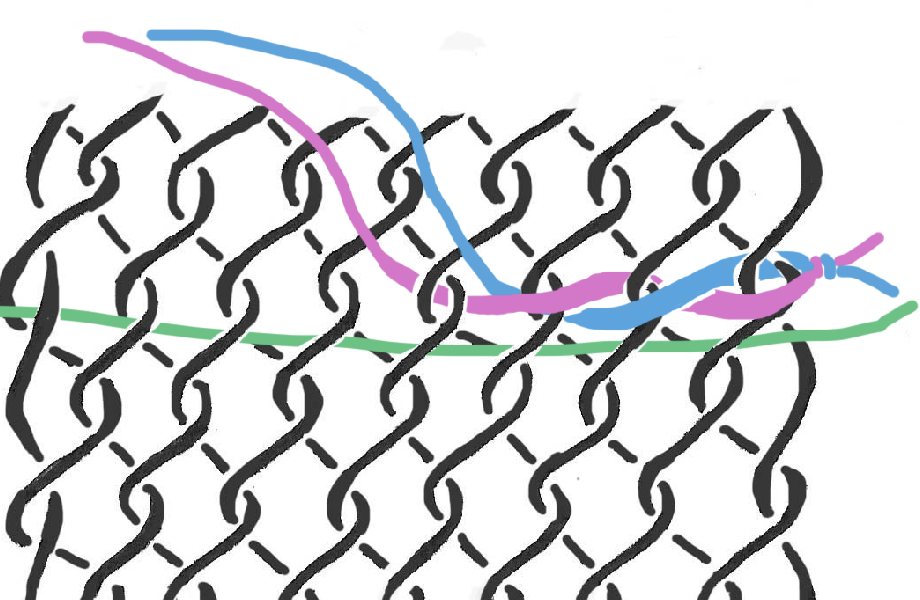

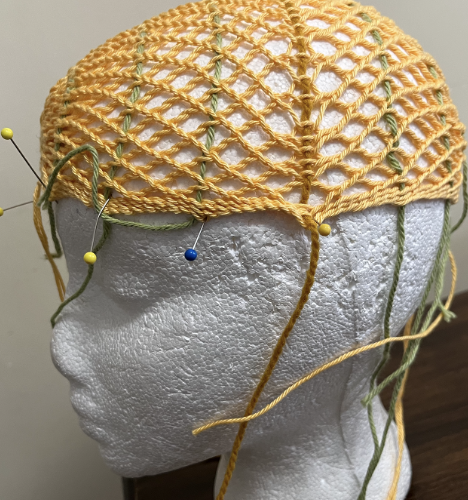

The portrayal of Jacob Fugger by Albrecht Drürer leads me to think that Mr Fugger wore a sprang bonnet. I tried to make a similar bonnet. I interpreted the heavy lines in the bonnet as lines of horizontal twining in a sprang bonnet. When I tried this myself I found that there may be a reason for the twining in the sprang bonnet, as you will see. Thinking about approaches to incorporate horizontal twining into the sprang cloth, I thought of two ways to do this. One way (method #1) is to create a line of weft twining as I created the cloth. The other way (method #2) is to add the twining stitches after completing the sprang. The twining stitch does not have the stretch of the sprang cloth. Maybe, indeed, this was the whole idea of the twining line. This risk of method #1 is that the line of twining is too narrow for the desired width of the bonnet. I found method #2 to be more effective, in that I could place the sprang cloth on a head shape (styrofoam head) and then work the twining stitch at the desired tension, creating the desired width of the cloth, fitting the bonnet to the head. How did I work the twining stitch? How do you tie the bonnet on the head? Two approaches come to my mind. If you want the ends of the band to pass all the way around the head, then I would pass both ends through the circle at the back of the head.

0 Comments

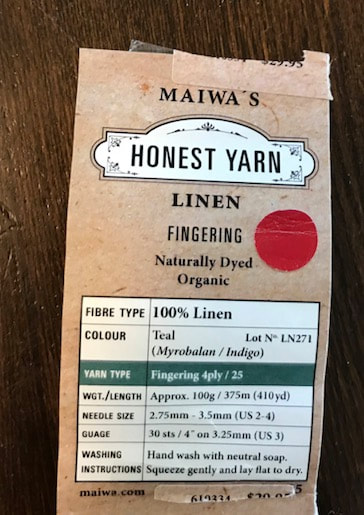

While in Vancouver earlier this year, I stopped in at Maiwa on Granville Island. I will be teaching a sprang class there next year. I wanted to have a look at their yarns, to evaluate their use for my students. I saw some lovely linen yarn. I decided to try to make yet another sprang shirt, using this linen yarn. OK, I purchased seven skeins. Wanting to use some of those colorful motifs from Coptic bonnets, I set up a multicolored warp. This piece will be the center back of the shirt. Now for two pieces to go on either side of the center back. These pieces will go over the shoulder, starting and ending at the hem of the shirt. Now for the front of the shirt. I decided to use the lighter green as the background for the front of the shirt. The first time I sewed the front into the shirt, there was a clear difference in tension (rows per inch) between the lower part of the front, and the side pieces. I re-sewed it a couple of times before getting it right. Now for two narrow pieces to go under the arms. And lastly, sleeves. I shaped the sleeves as I went along. I chained around the hem, to give a firmer edge to the shirt. I finished assembling the shirt, and washed it. Look for me this summer, sporting my new sprang shirt.

And here's a better image of that shawl I made last month, demonstrating perhaps some of the drape and flexibility of the fabric Photo by Chris Black

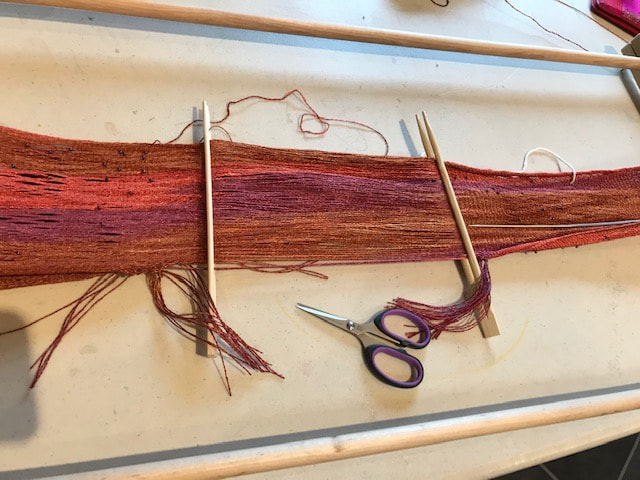

I now find myself at the FibreWorks Gallery near Madiera Park, British Columbia. I've been offered a short residency. This place is also called "The Yurts" because of the buildings that make up the campus. Planning to create a sprang scarf, I brought along yarn, beads, and the top and bottom of my sprang frame. I purchased 4 ft long dowels locally, and set to work. A sprang project needs the yarn mounted on the frame in an orderly fashion ... I needed to organize a first cross in the warp.  Ready to work. Ready to work. The weather was pleasant, I sat outside the FibreWorks Workshop Yurt, and worked. My pattern is inspired by pieces I saw at the Vesterheim Norwegian-American Museum in Decorah, Iowa. On Monday, FibreWorks was closed. I went along to speak to a spinners' guild, bringing them the good news of sprang. I worked on the shawl on Tuesday, and finished it by Thursday afternoon. The Weavers Circle meets at the FibreWorks Gallery on Thursdays, they watched as I cut the fringes, and tied the knots.

I visited the Kelsey Museum collection in the spring of 2016, went home and worked out the pattern for this hat, and then came back in the summer of 2017. At the occasion of my second visit, I took a photo of my replica beside the original. Actually I took two photos. In one of them, my replica is inside-out. If anyone is interested, my SprangLady website contains three tutorials that take you step-by-step, showing you how to do this twining technique on a background of interlinking. And I do still have the specific pattern for this bonnet.

I set out to make a new sprang top. In the past I'd say the choices are a V-neck, a boat-neck, or you cut out a hole for the neck. Last spring I made a shirt comprised of ten separate pieces of sprang. I was using 'estate yarn' (yarn of an unknown age and unknown fibre content). While I like the shirt, some of the threads are shattering ... the shirt is not standing up to wear. So I need another one. I purchased new yarn, nine skeins of Berroco Mixer, and made up nine pieces for this new shirt. Although it might seem overwhelming to set out to make nine pieces, it's no worse than knitting a sweater. I made a center-front piece and a center-back piece. These pieces start at neckline and hem, and work to a place somewhere near the waist. There are two pieces that go over the shoulder, working from hem to hem, and meeting at the shoulder. I also made two pieces, one to go under each armpit ... worked from armpit and hem towards the waist. These pieces were all flat warp. There are three circular warp pieces, two sleeves and a collar. Assembled together, they make a shirt. The basic stitch is a 2-2 twill, it has a comfortable amount of stretch. The Berroco is a mix of cotton, polyester, viscose and nylon, so I'm hoping it will stand up to washing and wearing. No need to hem this material. The pieces have selvedges all around.

En route to the British Museum, I stopped off to visit a friend who lives near Sheffield. I met Andy and Elaine a few years back. Elaine really wanted to know more about sprang. They were, at that time preparing to participate in an event, re-doing the battle of Marathon in Greece ... he was going to be one of the bad guys. I made him a pair of leggings, appropriate to the time period, and based on research by Dagmar Drinkler. It seems that Andy has worn these leggings to several events. Imagine my surprise when I read on the internet that sprang is not at all suitable for leggings! Andy showed me a post indicating that, with one broken thread, the pants will fall apart. This, I thought, is the perfect moment for a bit of testing, some experimental archaeological if you will. Andy allowed me to cut a thread in his leggings. To make it a fair test, I cut a thread at the knee, a place that would be affected by movement of the leg. Andy took a picture of me cutting the thread just in front of his left knee. Here you see the broken thread at the left knee. Andy then went outside to do some work in the yard. He cleared his deck of the leaves, and tended to his leaf-blowing machine. His leggings stayed on the entire time ... no falling apart ... no falling off. Indeed no increase in the size of the hole. The wool threads stayed put. Wool has a certain 'grabbiness' to it's surface, and the wool sock-yarn that I had used to make the leggings is no exception. Yes, I've seen silk sashes in museum collections with long vertical slits, where a thread broke. The slipperiness of silk as well as the simple interlinking structure would allow a slit to develop ... but the slit will only open up so far. At some point the length of the cut threads will, itself, prevent further un-doing. The structure of the zig-zag pattern in these leggings also helps prevent un-doing. I repaired the damage I had caused, tied a knot to mend the cut ends, and tucked the knot to the inside of the leggings. The damage is now repaired, the knot almost imperceptible.

A big Thank You to Andy Cropper for permitting me to carry out this test. I attended the 2017 CIETA conference, held at The Hermitage. Very interesting discussions of textiles as symbols of power. The Hermitage treated us to a special exhibit of their collections ... including a display featuring garments worn by Peter the Great. His military uniform included a sprang sash. The curator told me that the sash originally was tricolore: red, white, and blue. The fiber is silk with silver threads worked in. You can tell it is sprang, because one side features an S twist to the stitches, the other side features Z twist. There is a line at the shoulder where the S and Z meet.

The idea of sprang mittens has come up ... twice within the last week. A researcher colleague of mine found a pair of sprang mittens at a textile market in Bavaria. The seller had no provenance, but they look like sprang mittens in the collection of the Brussels History Museum, that date to the early 1800s. And then and e-mail from someone who took my sprang class earlier this year, Jenny from Regina. She sent me photos of her explorations since that class, including a photo of a lovely sprang mitten. Mittens are a great place to explore sprang. Make two rectangles, cut them apart, tying knots at the cut ends. Sew each piece into a tube, and voila, two fingerless gloves, aka, mittens. Use the opportunity to explore patterns.

Back from my recent travels, to Europe, and then to the TNNA conference in Columbus, Ohio.

In Columbus I met yarn store people from all across North America, what a conference! Maria Freitas of Meridan, Idaho, gave me a set of rayon threads to try in sprang. |

Categories

All

Archives

May 2023

Categories

All

|

RSS Feed

RSS Feed