|

The German Archaeology Institute in Berlin, and in particular individuals working on their Silk Road Fashion Project have invited me to work with them in the past. My job has been to create braided bands. In 2016 I assisted with the project recreating the outfit worn with the world’s oldest known pair of trousers. Check out https://www.youtube.com/watch?v=Pl7siWwzibs More recently I was asked to create braided bands of a structure that is a 2-2 twill with a vertical rib. The desired length for the bands varied from some 1.3 meters to 11 meters long.

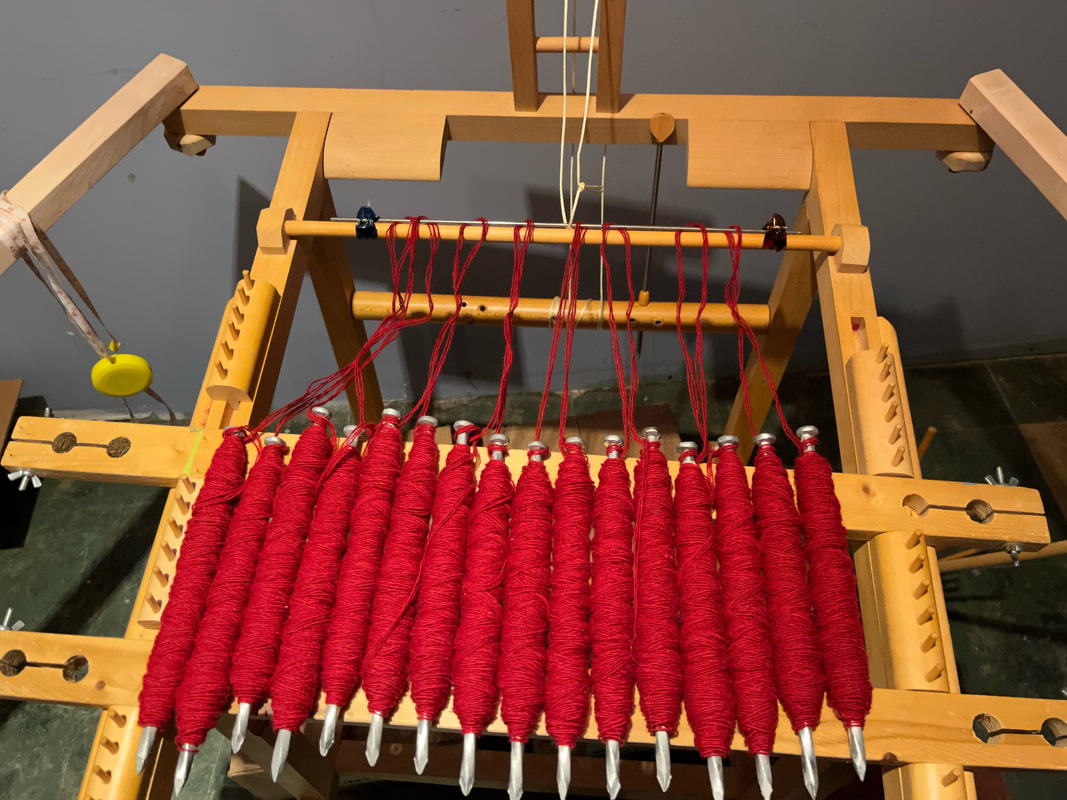

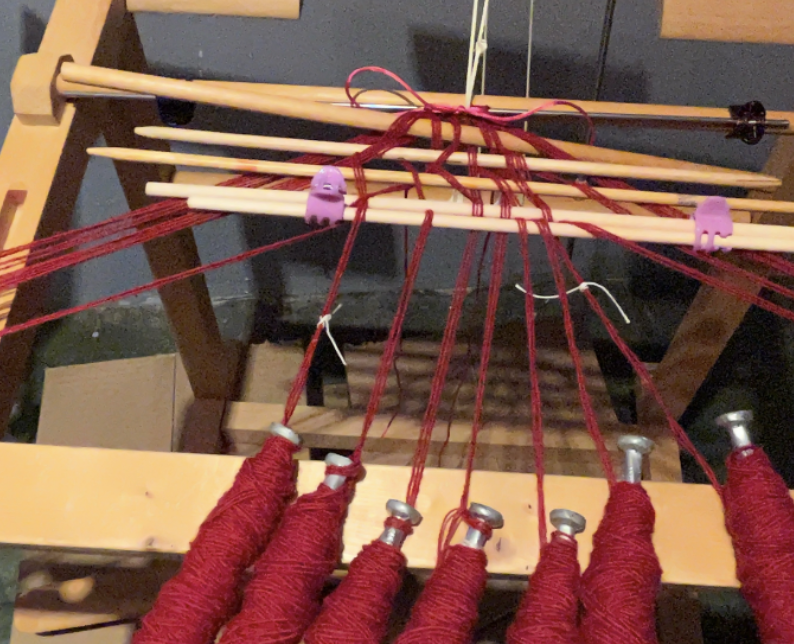

The result of this was the decision to create all the braids using a takadai, a Japanese braiding table. The takadai has the weaver set up the threads on bobbins, and the bobbins are placed around the takadai. The weaver manipulates the threads by moving the bobbins. The takadai facilitates the weaving by holding the bobbins in place.

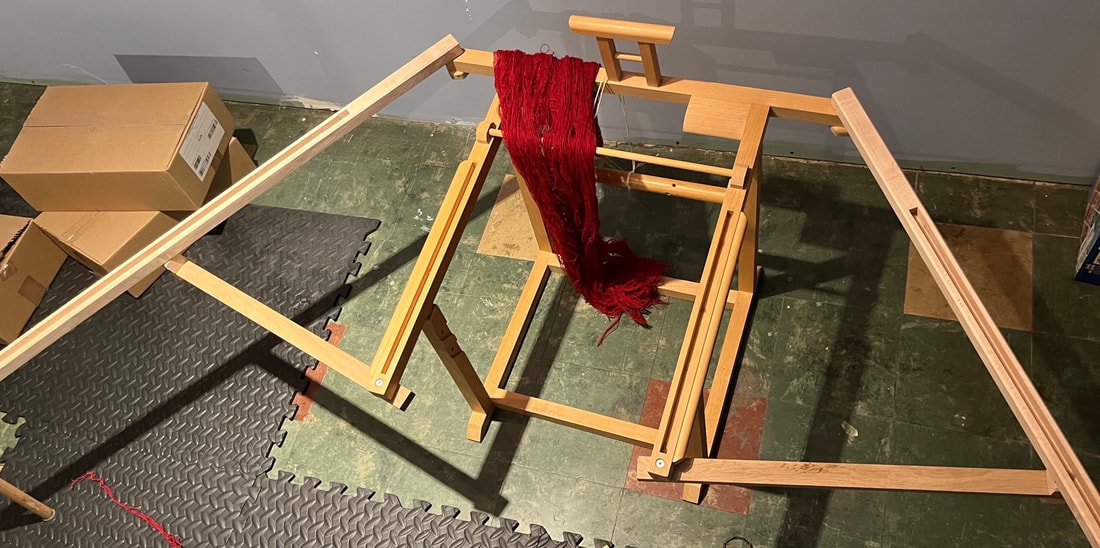

Back to Paul Shipman for adjustments to the longer arms. The longer arms, loaded with 92 bobbins, caused the takadai to tip over. This meant that I fitted the far ends of the long arms with legs, and it worked nicely. The great number of bobbins meant that each koma travelled a significant distance before moving to the bottom of the row. This meant that each bobbin descended a significant distance before passing as weft. All this resulted in a need to mount the takadai on boxes to allow for the space for the bobbins to descend.

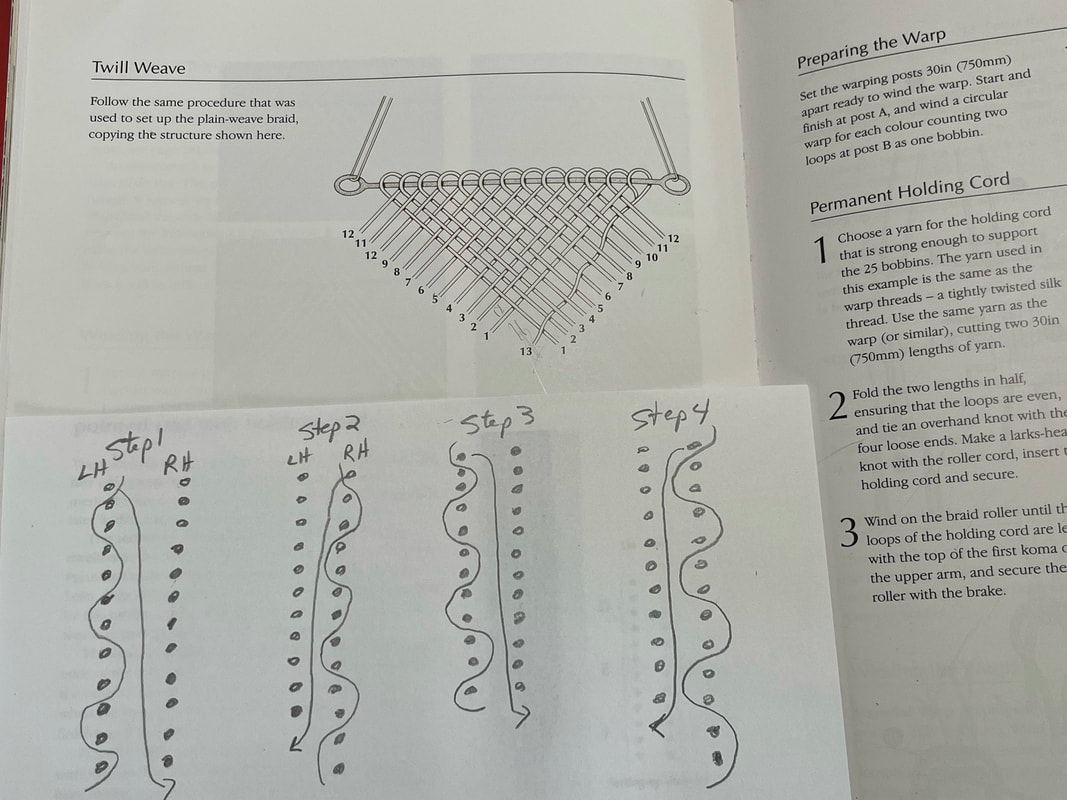

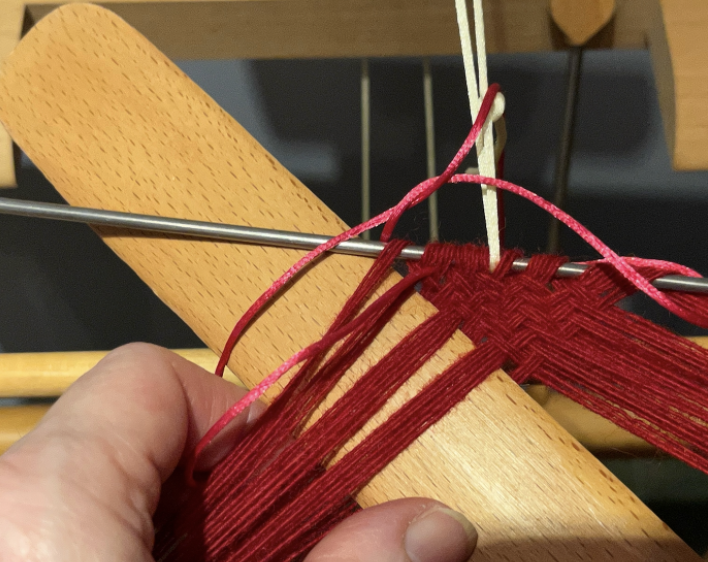

In the end I realized that I need to set up the warp using the rules for the Vertical Ribs. I measure out the warp threads two at a time. I mark the center of the two warp threads by tying a large loop. In this manner I begin with a set of pairs of bobbins.

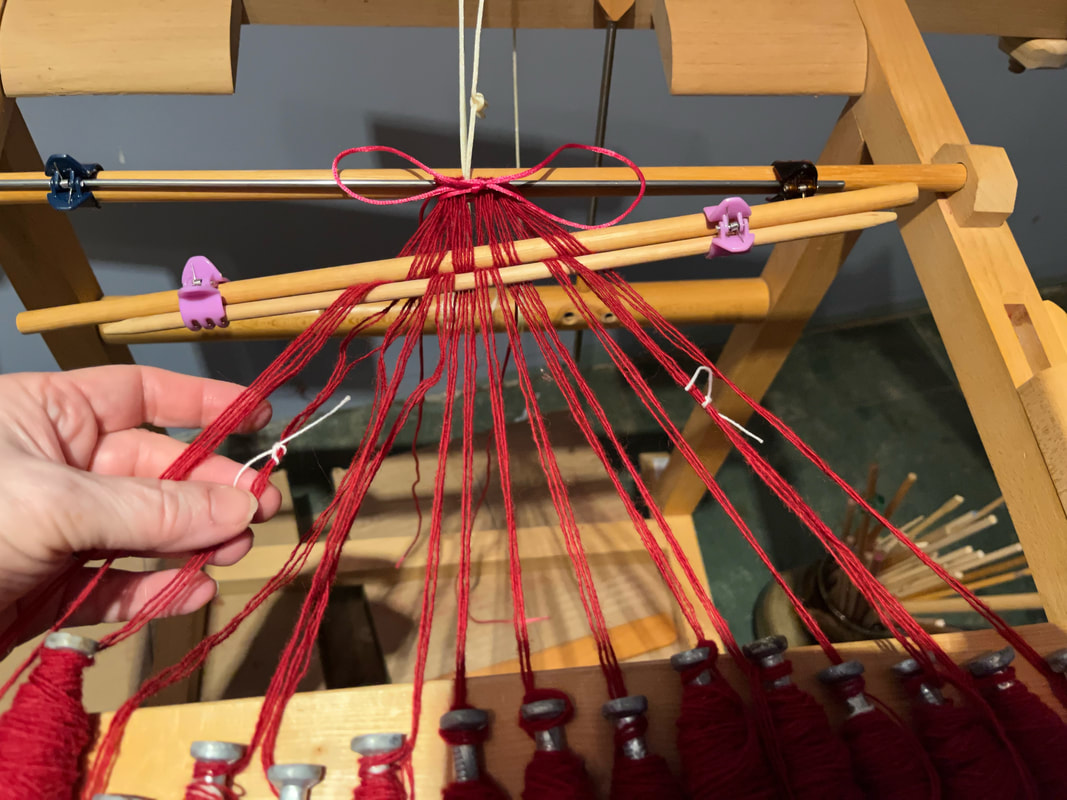

After each row of manipulation -Re-arrange the bobbins -Take the threads that have passed the triangle margin (white marked thread) off to the side When the margin threads (white marked threads) meet at the middle, your initial triangle is complete, and the structure has been established.

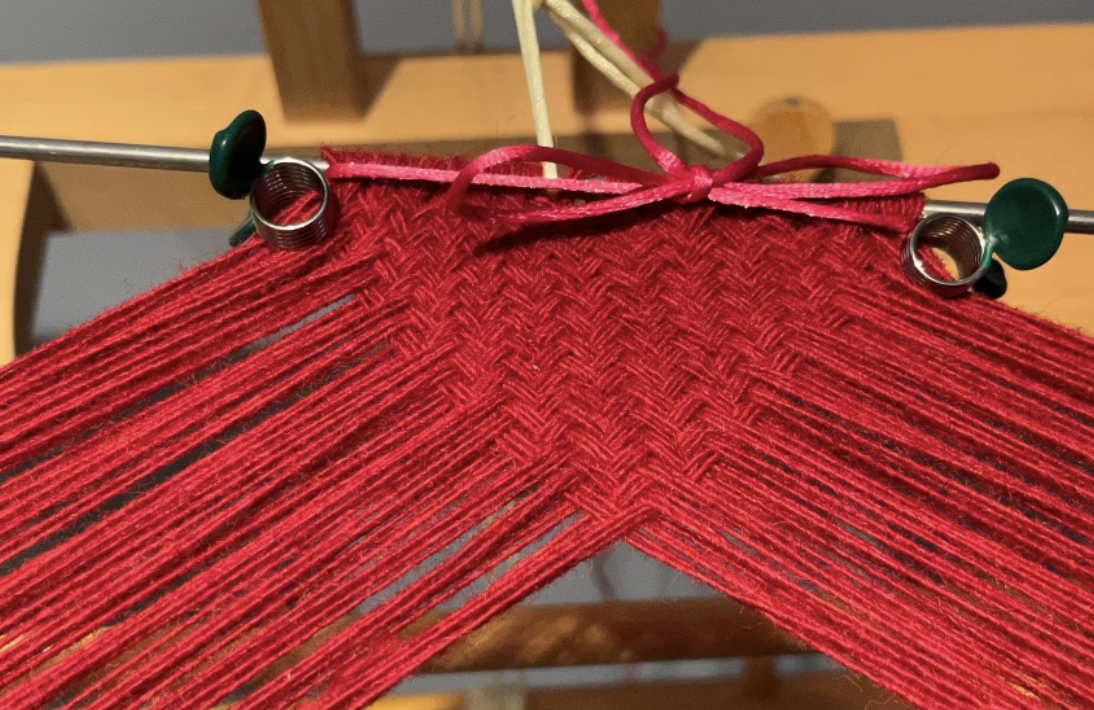

The next added thread will enter the cloth by passing under 1, then follow an over 2, under 2 path. Once the desired width was reached, it was a matter of putting in the time necessary to create the desired length. I needed to learn to check each row for accuracy. Common errors were inaccurate over-2-under-2, and Due to the fact that each bobbin holds three threads, another common error was splitting the 3 threads from a bobbin. The other challenge was to pack each row consistently. Beyond that it was a matter of working a couple of hours each day .... for several weeks ... to achieve the desired 11 meter length. I found that the stretch of the cloth caused a bit of sagging at the center of the cloth. I noted a slight ruffling of the center of the cloth between the tori and where it winds up at the back of the takadai. To minimize this I decided that I needed to support the cloth when winding on. To prepare for winding the cloth onto the back of the frame each time I inserted a stick into the current shed on either side of the cloth. I used these sticks to push upwards (towards the tori) on the cloth at the same time as I wound the cloth onto the back of the takadai. This minimized the amount of sagging at the center of the cloth as it wound onto the back of the frame.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Categories

All

Archives

May 2023

Categories

All

|

RSS Feed

RSS Feed